SAFE offers Customers a remote real-time monitoring and diagnostic service for all the parameters of the plant through a fast and easy system over a protected internet connection.

A complete overview of the system through its settings

Доступно 24/7, 365 дней в году

Ability to change all operating parameters of the system, as well as view data in "real time" mode

Multiple configurations related to presentation and display with the ability to easily download and export data to files. Ability to view both active alarms and history even when the system is offline

Email notifications of plant status based on both historical and current data. Sending automatic notifications when maintenance is required or when there is an alarm

Easy to use: 100% viewable on touch screen, PC, tablet and smartphone

SAFE is permanently committed to training Service Centre Managers , spare parts Managers and Customers to enable them to get the most out of their solution. With this in mind, a comprehensive theoretical and practical training course has been designed on how to operate machines and systems efficiently, effectively and safely throughout their life cycle. It includes three levels:

In-depth study of the characteristics of natural gas, operating principles as well as maintenance and troubleshooting operations.

It consists of a training plan for invasive interventions aimed at the elimination of potential faults, faults and alarms are given to the maintenance activities envisaged in the maintenance plan covering 4000 hours of operation.

It includes lessons on the main stock of spare parts, the activities related to on-site installation – including installation and configuration of the SCADA system – as well as the activities for a general overhaul of the system.

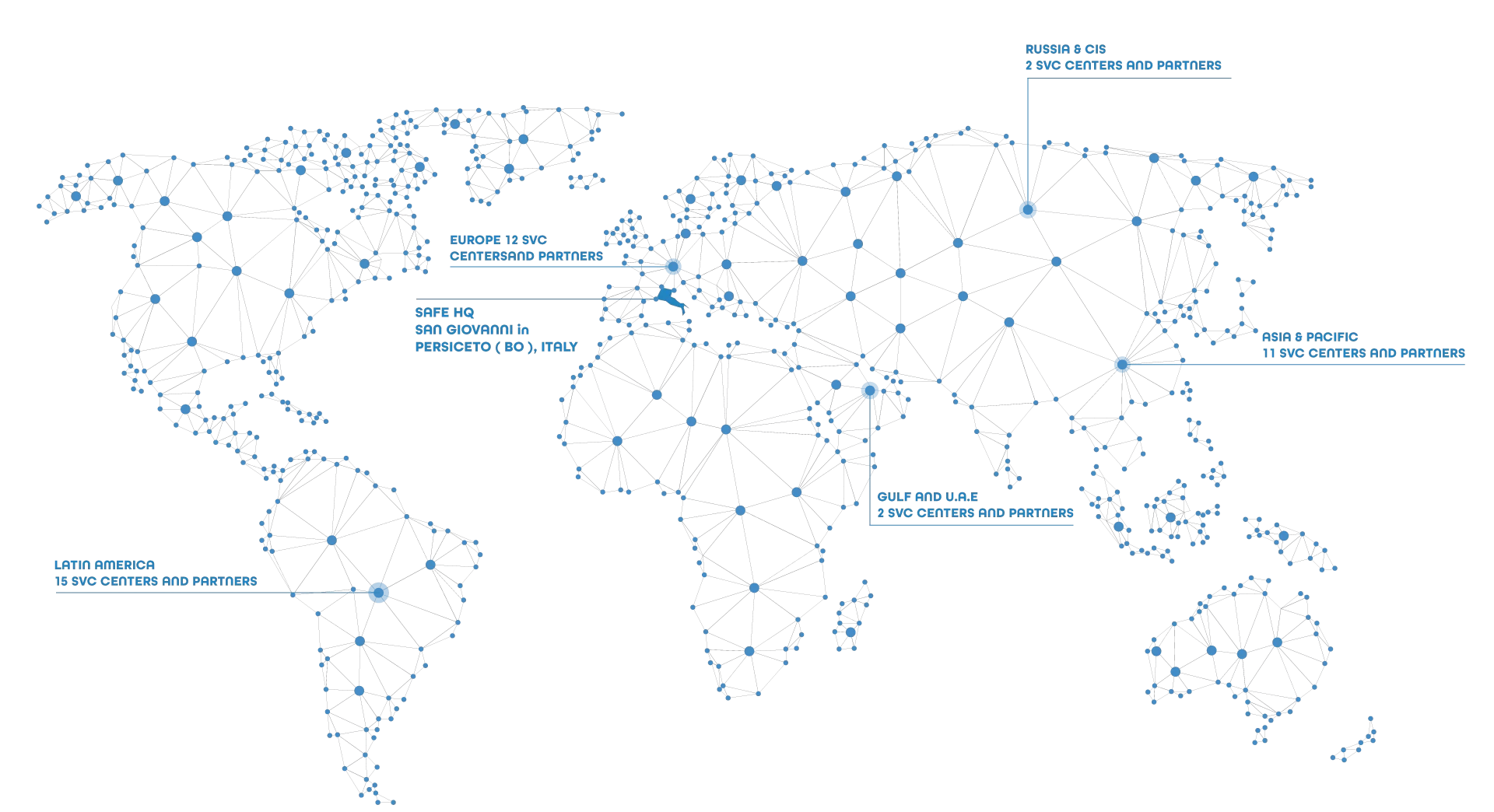

The quality of SAFE services also applies to after-sales activities through an extensive worldwide presence developed through the establishment of SAFE Official Centres, which ensure a prompt response all over the world. The network of Service Centres consists of three levels:

The first level, distributed and present locally, guarantees a stock of spare parts, a team of trained technicians and the ability to carry out planned maintenance activities.

The second level is distributed regionally and guarantees a stock of available spare parts together with a range of services, including the availability of SAFE certified technicians for planned maintenance operations.

The third level is represented by the HQ that guarantees, through coordination with the second level, the availability of a stock of spare parts, the presence of “senior” technicians trained periodically and who perform commissioning activities, plant start-up, as well as unplanned maintenance activities.