SAFE designs and develops compressors that can be integrated into a complete system according to customer specifications.

The compressors are manufactured using the latest technologies, which allow water cooling, high speed compressors and direct coupled solutions.

Made in-house with reliable raw materials and constant quality checks

Highly flexible and fully customizable

Quality control in the production chain

A team of highly qualified engineers to support the customer

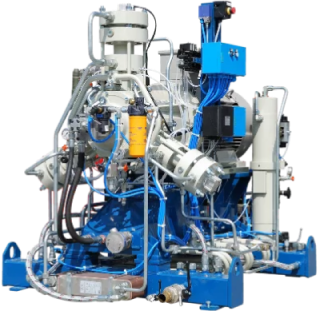

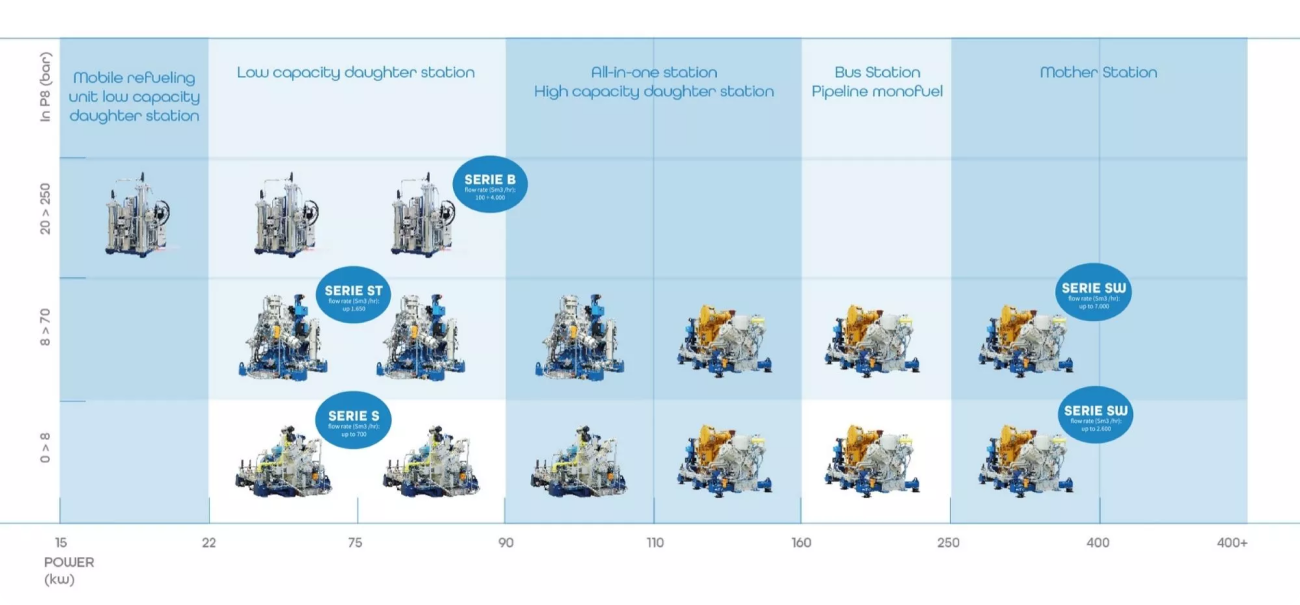

Small/medium size reciprocating compressors suitable for operating with low suction pressures. Certifications: EC, EAC, US

See the product

Small/medium size reciprocating compressors suitable for operating with high suction pressures. Recommended for MRUs. Certification: EC, EAC, US

See the product

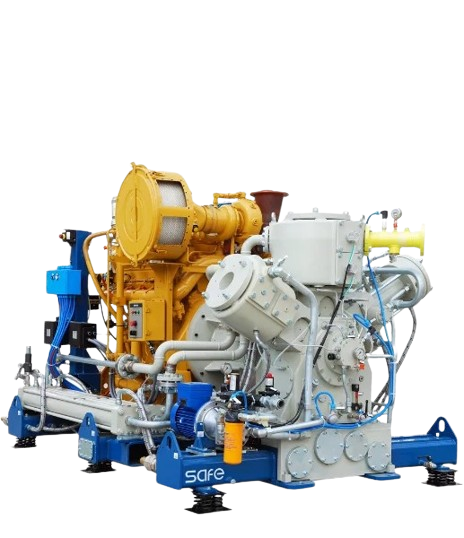

Mechanical compressors equipped with 2 or 3 cylinders positioned at 60°. They absorb 90 to 400 kW of power. They are the largest compression units produced by SAFE and can operate in a wide range of suction pressures.

See the product

High reliability hydraulic compressor for trailer unloading at daughter stations. Suitable for MRUs. Certifications: EC, EAC, US

See the product

SAFE has the ability and flexibility to design and adapt the compressor unit to the rest of the customer's system components and a complete solution can be supplied on request.

The ancillary elements and accessories that make up a complete system are:

The know-how built up by SAFE over more than 40 years also results in integrated solutions, tailor-made turnkey projects. These are ideal for the automotive CNG market with the aim of minimising dimensions while maintaining high standards of performance and efficiency.